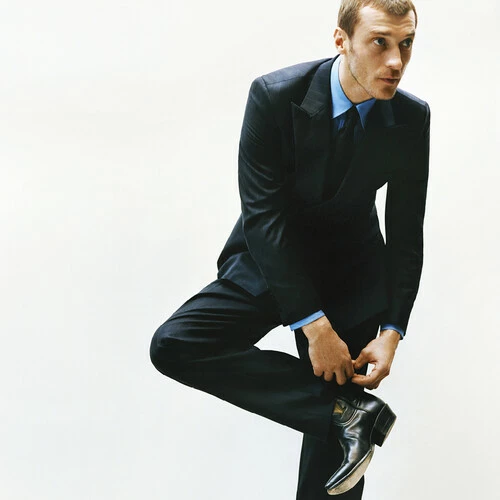

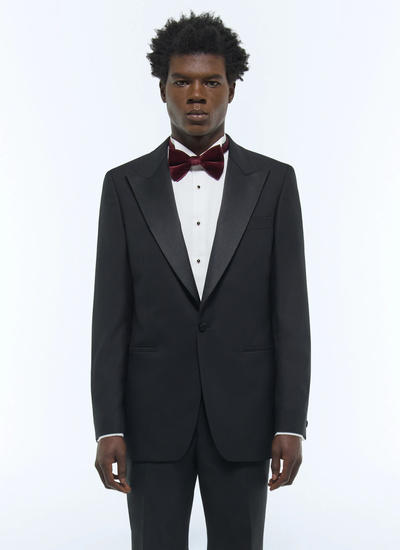

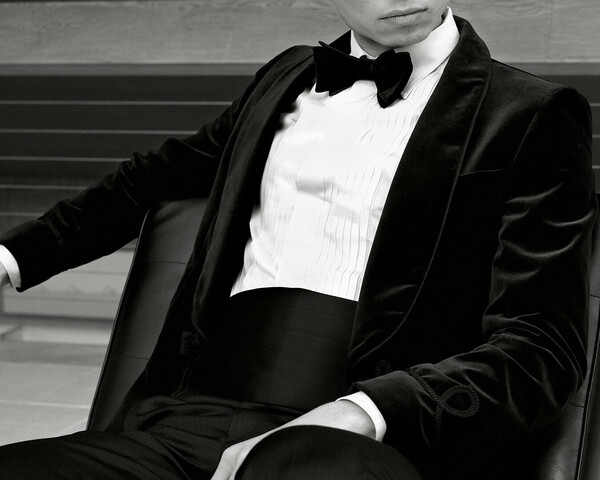

Semi-traditional construction: striking the perfect balance between tradition and modernity

At Fursac, each jacket reflects the rigorous tailoring expertise built over 50 years of history. The semi-traditional manufacturing we favor for many of our jackets perfectly illustrates our commitment: to offer a structured, comfortable, and durable piece, without ever sacrificing the modernity of the cut.

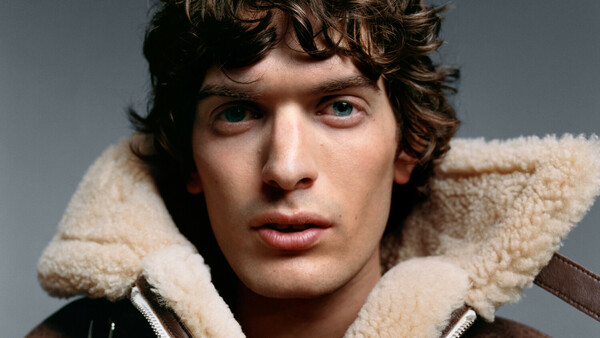

Noble materials, carefully selected

The excellence of our jackets also relies on the rigorous selection of materials. We mainly use fabrics of Italian origin, sourced from renowned mills known for their expertise. The fabrics are made from virgin wool, sometimes blended with other natural fibers such as linen, cotton, silk, and Mohair wool, while minimizing the use of synthetic materials to improve recyclability. Spun from Super 100, 110, and up to Super 150 yarns for certain references, these fabrics are recognized for their fineness and wearing quality.

We also prioritize strict traceability: the wool is tracked at least from the weaving stage, and for several of our references, all the way back to the original breeding farms. This level of transparency guarantees consistent and verifiable quality, while aligning with a responsible approach.

Quality, traceability, durability: a vision of clothing

This semi-traditional manufacturing process, rich in techniques derived from classic tailoring, allows our jackets to withstand the test of time and maintain their style season after season. It embodies our vision of clothing: a product designed to last and be worn, modern and elegant in style, deeply rooted in sartorial heritage.

Quality of materials, traceability of sourcing, durability of construction—every detail matters and reflects our commitment to a responsible and demanding wardrobe.